Why Timing is Everything: The Importance of Coordinating Deliveries in System Integration

Why Timing is Critical in System Integration

System integration involves bringing together multiple components—such as hardware, software, and network systems—to function as a unified whole. For this to happen effectively, the delivery of these components must be timed to match the project’s implementation phases. Here’s why:

1. Avoiding Delays and Downtime

When deliveries don’t align with project milestones, it can cause significant delays. For instance, if key hardware arrives late, it can halt installation work, leaving engineers and technicians waiting. This not only extends the project’s timeline but also increases labour costs as resources are tied up. Proper timing ensures that equipment arrives just when it’s needed, allowing installation and testing to proceed without interruptions.

2. Managing Storage and Handling Issues

If equipment is delivered too early, it may need to be stored, which can pose logistical challenges. Not all sites have the capacity to store large quantities of equipment, and improper storage can lead to damage or loss. On the other hand, late deliveries can lead to rushed installations, increasing the risk of errors. Coordinating delivery schedules ensures that equipment arrives on-site when there is adequate space and personnel to handle it properly.

3. Optimising Resource Allocation

Projects often have limited personnel assigned to different tasks. Coordinating deliveries allows project managers to allocate resources efficiently, ensuring that teams are ready to begin installation as soon as the equipment arrives. This reduces idle time and makes the best use of skilled workers.

The Benefits of Well-Coordinated Deliveries

Timing deliveries to align with project phases can bring several advantages:

1. Streamlined Project Workflow

When components arrive according to schedule, the project can progress seamlessly from one phase to the next. This streamlining reduces downtime between stages and ensures that each task can be completed in the proper order. For instance, delivering cabling equipment before network hardware ensures that all infrastructure is in place before the system is configured.

2. Reduced Risk of Project Bottlenecks

A delay in one phase of a project can create a domino effect, causing bottlenecks that impact subsequent tasks. Coordinated deliveries help mitigate this risk by ensuring that dependencies are met and that each phase of the project can proceed on time.

3. Cost Savings

By avoiding delays and storage costs, businesses can significantly reduce project expenses. With better resource management and fewer interruptions, the project can stay within budget and meet its deadlines.

4. Enhanced Flexibility and Contingency Planning

Having a well-thought-out delivery schedule makes it easier to adapt to changes. For instance, if a particular phase is delayed, you can adjust the delivery timing of the next batch of equipment without causing disruptions. This flexibility is crucial in large projects where unexpected issues are almost inevitable.

Best Practices for Coordinating Deliveries in System Integration

To make the most of your system integration project, it’s essential to manage delivery logistics effectively. Here are some best practices to help you coordinate deliveries and maintain a smooth project flow:

1. Develop a Detailed Project Plan

Start by mapping out each phase of the integration project and identifying key milestones. Establish clear deadlines for when each component needs to be on-site, and account for lead times. Work backwards from these deadlines to set realistic delivery dates, factoring in potential delays such as customs clearance or transport issues.

2. Communicate with Suppliers and Logistics Partners

Open and ongoing communication with suppliers and logistics partners is crucial. Make sure that everyone involved understands the project’s timeline and requirements. Provide suppliers with a delivery schedule that includes buffer times for unforeseen circumstances. This ensures that any issues can be addressed quickly without derailing the project.

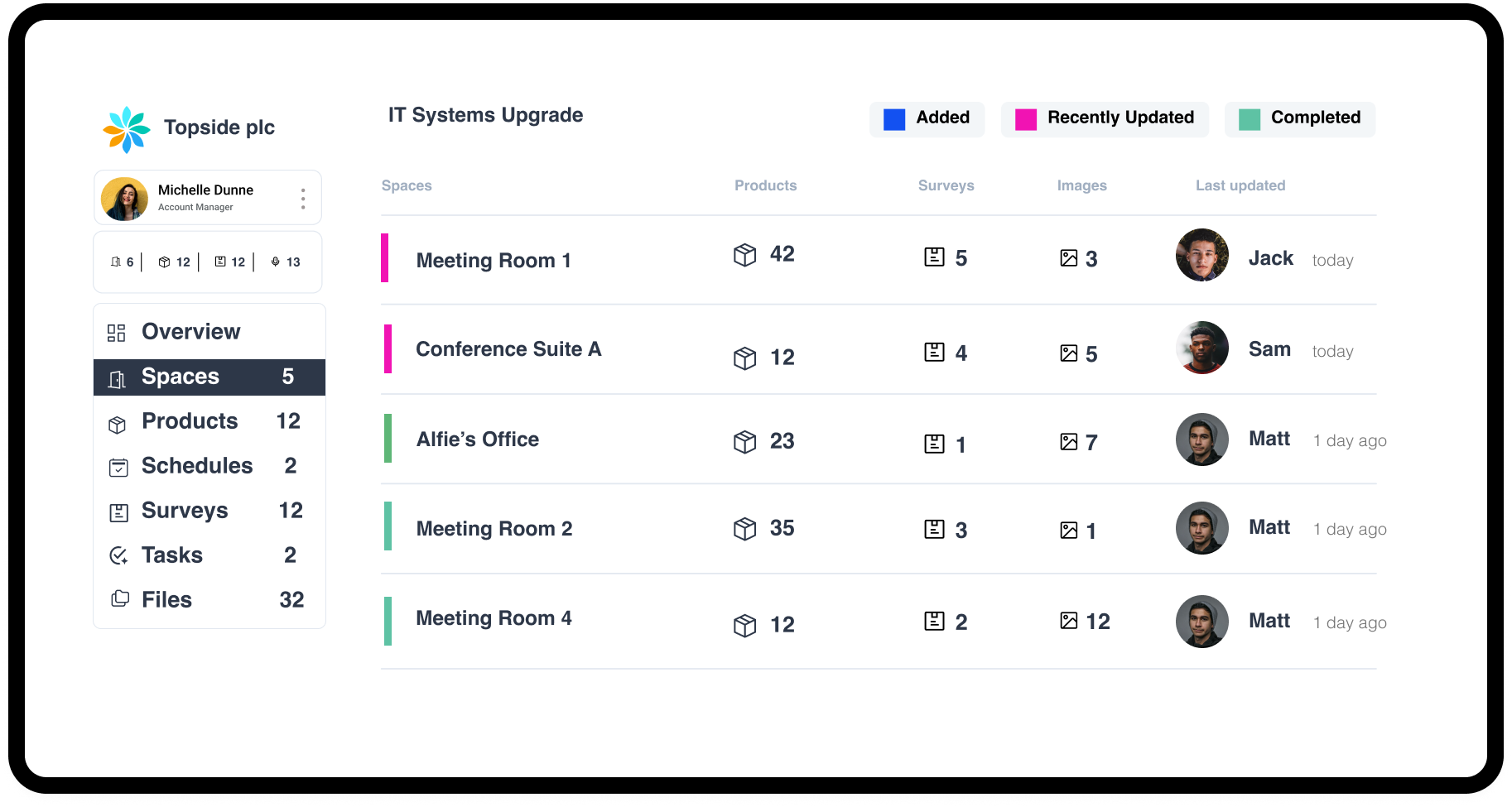

3. Use Project Management and Logistics Tools

Take advantage of digital tools to track deliveries, monitor project timelines, and manage inventory. Project management software can help coordinate tasks and schedules, while logistics tools can provide real-time tracking of shipments. This visibility allows for proactive adjustments to the schedule as needed.

4. Conduct a Pre-Installation Site Survey

Before scheduling deliveries, conduct a site survey to assess storage space, access points, and any logistical challenges. This will help in planning where equipment should be delivered, stored, and staged for installation. The survey also allows you to coordinate with site personnel to ensure the delivery area is prepared.

5. Implement a Just-in-Time Delivery Approach

For large-scale integration projects, consider using a just-in-time delivery strategy, where components are delivered only when they are needed for installation. This approach reduces storage requirements and minimises the risk of damage or loss. However, it requires careful coordination with suppliers and transport companies to ensure timely deliveries.

6. Prepare for Contingencies

No matter how well you plan, unexpected delays can still occur. Have contingency plans in place for potential disruptions, such as backup suppliers or alternative storage locations. Additionally, build some buffer time into your schedule to accommodate any last-minute changes without impacting the overall project timeline.

Real-World Example: The Impact of Coordinated Deliveries

Imagine a large office building undergoing a complete IT infrastructure overhaul. The integration involves new network hardware, cabling, and software installations. If the cabling equipment arrives too late, the installation team is unable to proceed, causing the entire schedule to shift. Alternatively, if the network equipment arrives too early, it may have to be stored in a temporary location, risking potential damage or loss.

By coordinating deliveries according to the project phases, the cabling arrives first, followed by the network equipment and software installations, ensuring a smooth and uninterrupted workflow. This approach minimises storage issues, reduces labour costs, and keeps the project on schedule.

Conclusion

In system integration projects, timing truly is everything. Coordinating deliveries with the different phases of installation is crucial for avoiding delays, optimising resource allocation, and maintaining project momentum. By developing a detailed project plan, communicating effectively with suppliers, and using logistics tools, businesses can ensure that all components arrive on time and in the right sequence.

Taking the time to plan and manage delivery schedules will not only streamline the integration process but also result in cost savings and improved project outcomes. So, before embarking on your next integration project, make sure timing is at the top of your agenda.

Get started

Ready to supercharge your Integration business?

An array of tools designed to simplify internal processes, enhance quality control, and boost stakeholder engagement. Generate more accurate customer data and project insights while enhancing internal communication and

efficiencies.